Selection, Installation & Use Guide

Emergency Eyewash & Shower Equipment

Contents

Contents

Foreword

The need for emergency eyewash and shower devices is real. More than 21,800 cases in which U.S. workers were exposed to chemicals or chemical products were reported from 2021-2022, according to the U.S. Bureau of Labor Statistics (BLS). Of these, 20,950 experienced chemical exposures to the eyes or skin. According to government data, from 221-2022, American workers reported more than 48,600 eye injuries, and nearly one quarter were a result of chemical exposure.

The Occupational Safety and Health Administration (OSHA), 29 CFR 1910.151, requires that: “Where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use.” Some States also require emergency eyewash and shower equipment in workplaces where there are irritants or chemicals that are toxic by absorption.

Many states require the use of ANSI/ISEA Z358.1 compliant equipment. The International Plumbing Code (IPC) and the Uniform Plumbing Code (UPC) recognize hazards of caustic and corrosive exposure. IPC, section 411, and UPC, section 416, require the use of ANSI/ISEA Z358.1 compliant equipment whenever eyewash or shower equipment is needed.

U.S. Department of Energy (DOE) health and safety regulations, found in 10 CFR 851, follow most OSHA regulations. DOE has stated “where this [injurious exposure of corrosive materials to the eyes or body] potential exists, there must be an emergency eye wash facility that meets ANSI standards.” The U.S. Navy and U.S. Air Force also require the use of ANSI/ISEA Z358.1.

In addition, an emergency eyewash or shower, placed in the correct location not only minimizes an injury, but the proper selection, placement, maintenance and use of emergency eyewash and shower equipment can reduce the cost of workplace injuries.

Corrosive Exposures

Emergency eyewash and showers are part of an employer’s worker protection program. Along with safety eyewear, gloves and protective apparel, employers should install emergency eyewash and shower equipment.

ANSI/ISEA Z358.1-2014 follows established medical opinion that a 15-minute flush of the eyes and body with flushing fluid will provide emergency first aid mitigation of corrosive or caustic splash exposures.

The ANSI/ISEA Z358.1-2014 standard establishes dimensional and performance requirements to ensure that units provide sufficient flow of flushing fluid at a safe temperature and a spray pattern that is sufficient to flush the affected body parts without being injurious. It specifies performance requirements for control valves, so that units operate in 1 second or less and remain in operation until intentionally closed. It requires units that are capable of delivering flushing fluid for 15 minutes. Test procedures and certification requirements are included for performance parameters.

In addition, ANSI/ISEA Z358.1-2014 provides performance, installation, maintenance and use information for equipment used to minimize injury from harmful chemical exposures to the skin and eyes.

Job Hazard Analysis – A Key to Compliance

A job hazard analysis must be performed to make certain the equipment is accessible and operational as prescribed in the ANSI/ISEA Z358.1-2014 standard. A full job hazard analysis will allow you to determine what type(s) of emergency eyewash(es) and/or showers are needed, where and possibly in what quantity. The “Hazard Assessment” (on pg. 5) contains additional information on selecting the appropriate equipment for your facility.

The ANSI/ISEA Z358.1-2014 standard provides instructions that units must be properly installed, positioned to deliver flushing fluid in the required pattern and at a safe, tepid temperature, accessible within 10 seconds of a potential exposure, and identified with appropriate signage. Maintenance instructions provide guidance on periodic testing to ensure the proper function of the units; and employee instruction and training is required.

These requirements have evolved from years of experience in the design, manufacture and use of emergency eyewash and shower equipment, incorporating medical recommendations for timely and continuous irrigation of parts of the body exposed to potentially hazardous materials.

Purpose and Scope

The purpose of this guide is to provide guidance to users on the

need for proper emergency eyewash and shower equipment to

mitigate injury from splash and ocular incidents, to illustrate

eyewash and shower equipment systems, and to assist in the

proper selection, use and maintenance of emergency eyewash

and shower equipment.

NOTE: This document is meant as a guide only and does not

replace the current ANSI/ISEA Z358.1-2014 standard. Please

review the ANSI/ISEA Z358.1-2014 standard document for

specific requirements.

Definitions

ANSI/ISEA Z358.1-2014 contains the following definitions:

A system whereby a certification organization determines that a manufacturer has demonstrated the ability to produce a product that complies with the requirements of this standard, authorizes the manufacturer to use a label on listed products that comply with the requirements of this standard, and establishes a follow-up program conducted by the certification organization as a check on the methods the manufacturer uses to determine continued compliance of labeled and listed products with the requirements of this standard.

An independent third party organization that determines product compliance with the requirements of this standard with a labeling/listing/follow-up program.

An interconnected assembly of emergency equipment supplied by a single source of flushing fluid.

A supplemental device consisting of a flexible hose connected to a flushing fluid supply and used to provide fluid to irrigate and flush face and body areas.

A device specifically designed and intended to deliver flushing fluid in sufficient volume to cause that fluid to cascade over the entire body.

A device used to provide fluid to irrigate and flush both the face and the eyes simultaneously.

A device used to provide fluid to irrigate and flush the eyes.

The pressure in the water supply pipe near the water outlet while the faucet or outlet is fully open and flowing.

Potable water, preserved water, preserved buffered saline solution or other medically acceptable solution manufactured and labeled in accordance with applicable government regulations.

Equipment designed to allow the emergency device to operate under freezing conditions.

A means to protect flushing fluid in an apparatus from freezing and rendering it inoperable. This can be achieved through several means including mechanical valves and electrical heat tracing.

Any substance or compound that has the capability of producing adverse effects on the health and safety of humans.

A supplementary device that supports plumbed and/or self-contained units, by delivering immediate flushing fluid to the eyes or body. These devices do not meet all of the ANSI/ISEA Z358.1- 2014 standard’s requirements, such as providing a 15-minute flush/drench and flushing both eyes simultaneously.

A term used to describe equipment that is connected to a continual source of potable water.

Water that is suitable for drinking.

A valve that closes automatically when released by the user.

A term used to describe a stand-alone device containing flushing fluid.

A flushing fluid temperature conducive to promoting a minimum 15 minute irrigation period. A suitable range is 16 – 38º C (60 -100º F).

Download ANSI/ISEA Z358.1-2014

Hazard Assessment

Please consult with a safety and health professional or a representative from one of the manufacturers listed in this guide for a complete hazard assessment.

Some of the considerations, which are also part of a job hazard analysis, include, but are not limited to the following:

- Identify each operation where hazardous materials are generated and/or present.

- Do the safety data sheets of materials used in your facility call for immediately flushing or drenching upon exposure to the skin or eyes?

- Is the hazard likely to expose the eyes, face, body or combination or all three?

- How many employees could be exposed to these hazards at the same time?

- Is there plumbing near the potential exposure? (This will determine if you can choose between a plumbed or self-contained unit, or if you must use a self-contained unit.)

- Review the work area where the hazard is present. Can the employees reach the eyewash/shower station within 10 seconds (about 55 feet) via a clear unobstructed path?

- Review the surrounding environment. Will the eyewash/shower station be exposed to heavy dust or debris? Will it be outdoors and exposed to freezing or extremely hot temperatures?

Equipment Types and Features

If an employee is splashed with an injurious material, the optimal emergency first aid measure is to flush the affected area. The following types of ANSI/ISEA Z358.1-2014 complaint devices are designed to deliver 15-minutes of flushing or drenching fluid at the optimal temperature, velocity and spray pattern to make certain an affected worker receives the needed first aid.

EQUIPMENT TYPES

The criteria for equipment placement, delivered flushing fluid temperatures and spray patterns established in the ANSI/ISEA Z358.1-2014 standard apply to primary types of equipment capable of providing adequate rinsing of contaminated eye or skin tissue. These devices are capable of delivering a 15-minute flush. There are other devices, such as personal wash units that can aid with immediate decontamination of a victim, but because of their inability to maintain a fluid supply for 15-minutes, they are considered to be supplemental.

Emergency Showers

Emergency shower equipment is appropriate in situations where the potential hazard of full-body chemical exposure exists. When properly installed, the shower will provide an adequate flow of flushing fluid, dispersed in such a pattern to maximize rinsing of the body for a minimum of 15 minutes. Delivery of the flushing fluid can come from overhead, the side(s) or both, providing that the pattern meets the stated minimum height and dimensional requirements of the ANSI/ISEA Z358.1-2014 standard.

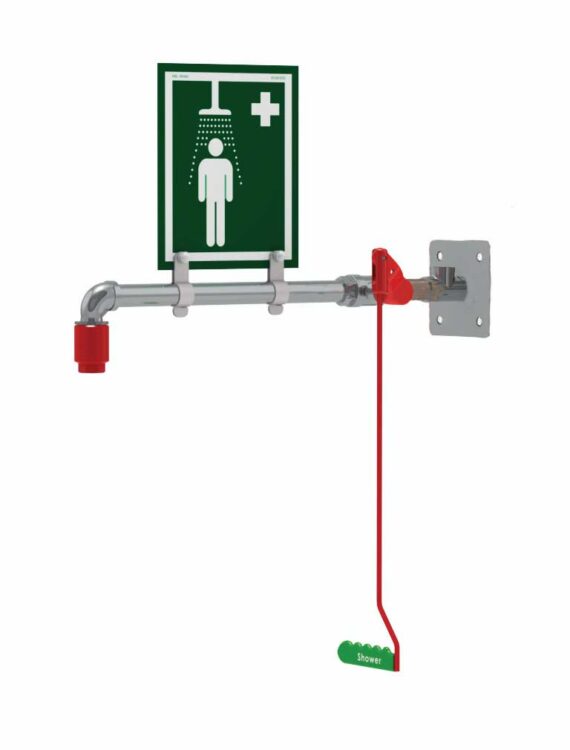

Plumbed Emergency Showers

An emergency shower permanently connected to a source of flushing fluid. Plumbed emergency showers can be floor mounted, wall mounted or ceiling mounted.

Self-contained Emergency Showers

An emergency shower that contains its own flushing fluid. The fluid must be refilled or replaced after each use.

EYEWASH EQUIPMENT

Eyewash stations are likely to be found in settings where impairment of the eye tissue is likely but the possibility of full-body exposure and contact is minimal. Typical eyewash stations will provide equal amounts of fluid to both eyes at a rate adequate enough to rinse the eyes for 15 minutes. The velocity of the flushing fluid stream is low enough such that the user could comfortably hold his or her eyes open in the stream(s) without causing discomfort.

There are two types of eyewash equipment:

Plumbed

Plumbed emergency eyewash units are fixed position installations where the flushing fluid supply provides adequate volume and pressure to meet the manufacturer’s specification and the 0.4 gpm minimum 15 minute flow as specified in ANSI/ISEA Z358.1-2014.

- The plumbed eyewash could be mounted in a variety of methods to include support by the supply piping, a mounting bracket to support the equipment to a fixed object such as a wall or counter top, or a pipe stand assembly referred to as a pedestal mount.

- The eyewash may include a receptacle (‘bowl’) for collection and direction of spent fluid away from the eyewash user, typically into a drain or collection sump.

The eyewash nozzles must be protected from airborne contaminants, usually by such methods as integrated covers.

Self-Contained

Self-contained emergency eyewash units contain a large volume reservoir of flushing fluid within the unit and are designed to provide a continuous 15 minute flow of flushing fluid.

These self-contained units come in a variety of configurations:

- They can be permanently fixed in place or be portable units designed to be easily moved from one location to another.

- The flow of fluid from the reservoir to the spray nozzle can be delivered under pressure or via gravity feed.

- They can be wall mounted, pedestal /table mounted or mounted on a cart to maximize mobility.

- The flushing fluid can be any approved flushing fluid such as potable water, preserved water, preserved buffered saline solution, sterile buffered saline solution or other medically acceptable solution.

Selection of the appropriate self-contained emergency eyewash unit should be determined by the specific requirements of the user’s application.

Faucet Integrated/Mounted Eyewashes

In many laboratory, clinic and school applications, you will find eyewashes located on the back of a sink as part of the faucet.

It is important to know that faucet mount products must comply with all aspects of ANSI/ISEA Z358.12014 including 1 second activation.

EYE/FACE WASH EQUIPMENT

These devices are designed to deliver a minimum 3.0 gpm stream of fluid targeting the ocular cavity, eyes and face. Some fixtures divert a central stream of flushing fluid into several smaller streams to provide a gentler rinse, while others provide a more directed stream of water to the eye cavities. Other systems implement streams using an aerated system to disperse the flushing fluid across the face to rinse contaminants off. Regardless of the method, an eye/face wash must disperse a minimum of 3.0gpm.

Plumbed Eye/Face Washes

An eye/face wash unit permanently connected to a source of flushing fluid.

- The plumbed eye/face wash could be mounted in a variety of methods to include support by the supply piping, a mounting bracket to support the equipment to a fixed object such as a wall or counter top, or a pipe stand assembly referred to as a pedestal mount.

- The eye/face wash may include a receptacle (‘bowl’) for collection and direction of spent fluid away from the eyewash user, typically into a drain or collection sump.

Self-contained Eye/Face Washes

An eye/face wash unit that contains its own flushing fluid. The fluid must be refilled or replaced after each use.

Combination Shower and Eyewash or Eye/Face Wash Units

Drench shower and eyewash or eye/face wash combination units are typically considered where there is a risk of exposure to the body, eye and facial area. If injurious materials are Selection, Installation and Use Guide: Emergency Eyewash and Shower Equipment 8 present, there is a possibility that a complete body flush will be required and must be present and ready for use, should an emergency occur.

SUPPLEMENTAL EQUIPMENT

Personal Wash Units

Personal wash units are not replacements for ANSI/ISEA Z358.1-2014 compliant emergency eyewashes and showers, but supplement their use. Frequently, personal wash equipment is closer to the injured person and can provide treatment until the injured person can be moved to the location of primary equipment.

Personal wash equipment may be ideal for the following situations:

- As a first response, in which immediate rinsing is needed before a person can get to the primary device.

- When a person is enroute to a medical facility after using primary equipment.

- In accident response in areas where primary equipment does not exist such as an outdoor worksite.

Drench Hoses

Drench hose products can be used as supplemental devices or compliant devices depending on their design. To be a compliant device, the drench hose must contain an eye or eye/face wash that complies with all the performance requirements of ANSI/ISEA Z358.1-2014. The hose allows for more flexibility during use as the rinse can be targeted to specific area(s) of the body.

As a supplemental device, a drench hose should support compliant eyewash or drench shower, but it will not replace it. Single head drench hoses attached to a primary fixture or mounted to the wall serve an important supplemental purpose in particularly toxic, hazardous environments, providing additional coverage where necessary.

To prevent cross connection contamination, employers should install a drench hose with a backflow preventer that meets local codes and ordinances.

OPTIONS/ACCESSORIES FOR PRIMARY EMERGENCY FIXTURES

These are options selected by the equipment owner to further enhance the overall effectiveness of the chosen emergency flushing fixtures.

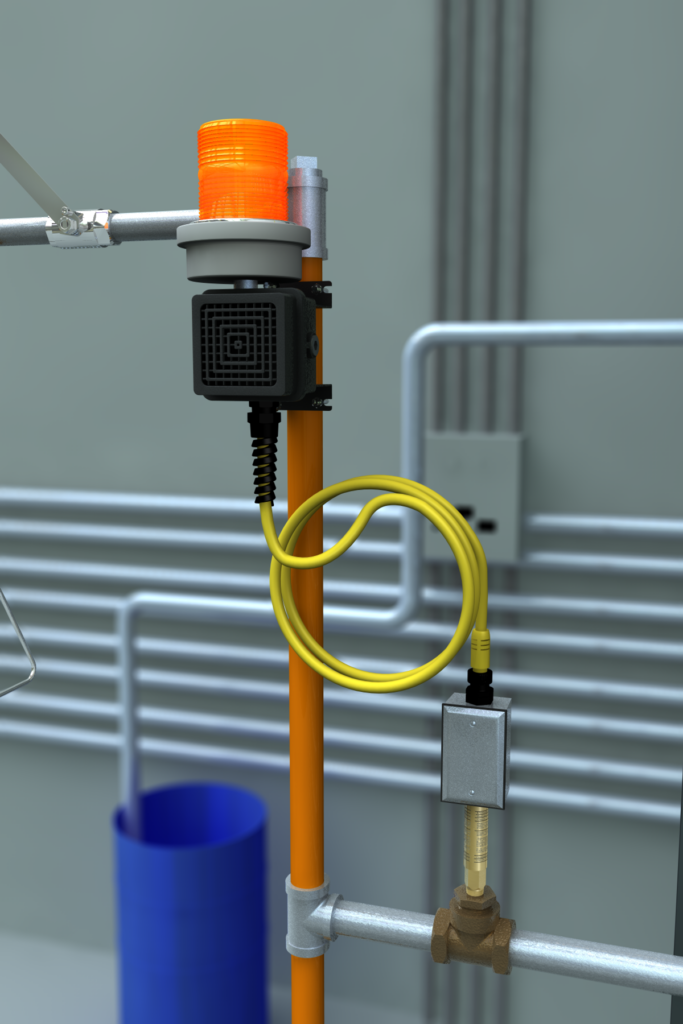

Alarms

Alarms are visual and/or audible devices which signal usage of the equipment within the immediate area and turn on upon activation of the emergency fixtures. Activation can be accomplished by flow switch, proximity switch or wireless device. Provisions can be made to send a secondary signal to a remote location to notify additional response personnel. In schools, eyewash and shower usage alarms can thwart vandals.

Backflow Preventers

To prevent cross connection contamination, drench hoses of all types are typically installed with a backflow preventer that meets local codes and ordinances.

Dust Covers

While ANSI/ISEA Z358.1-2014 requires the eye and eye/face nozzles to be protected from airborne contaminants, full bowl dust covers provide additional protection from debris and trash accumulating within the eyewash bowl.

Eyewash Test Gauge

An eyewash test gauge is a device designed to specific dimensions to test the spray pattern of eyewashes. An illustration of this device can be found in the ANSI/ISEA Z358.1-2014 standard.

Foot Controls

These devices provide another means of activating the emergency fixtures by stepping on a foot pedal which activates the stayopen valves of the eye, eye/face wash and or shower. These can be used in conjunction with standard emergency fixture activation methods.

Freeze Protection for Self-Contained Emergency Eyewash Units

Heated blankets cover self-contained eyewash units and keep the flushing fluid from freezing in cold environments.

Freeze Protection for Plumbed Equipment

Several methods of freeze protection for plumbed equipment are available:

Electrical heat tracing is the most common means of freeze protecting emergency showers and eyewashes. The units are wrapped with heat trace cable and insulation and then are jacketed with an ABS shell to protect them from the environment. When using electrical heat tracing, care must be taken to ensure that units with proper explosion proof ratings are selected. An additional consideration is to make sure that the unit is equipped with secondary freeze or scald protection devices to protect it in case of power outages or extreme exposure to solar radiation.

Alternate means of mechanical freeze protection are also available.

Frost Proof Hydrant designs rely on buried supply lines and deliver water to the equipment only when the unit is activated by an above ground lever. The valves and water supplies are buried below the frost line where they are resistant to freezing. After use, all of the water is drained out of the unit.

Another common means of freeze protection involves locating the emergency equipment on a wall adjoining a heated space. The emergency equipment is located outdoors but the water supply and actuating valves are in the heated space. After use, a drain port removes standing water from the emergency equipment to prevent freezing.

Modesty Curtains

It is considered critical that contaminated clothing is removed as soon as possible after exposure to injurious materials. Modesty curtains provide an area of privacy around the emergency fixture that encourages the afflicted individual to remove their clothing without delay due to modesty or embarrassment.

Plumbed Hot and Cold Fluid Protection

Devices can be added to emergency fixtures that prevent the flushing fluid from reaching scalding or freezing temperatures. These devices operate automatically and will continue to discharge and replenish water in the unit until a safe temperature is reached.

Normally a valve to protect against freezing will activate when water temperatures drop below 40F and one to prevent scalding will activate at 95F. Once the water temperature returns to a safe range, the valve will automatically shut off.

Shower Tester

To facilitate weekly testing of emergency shower equipment, manufacturers recommend the use of a drench shower tester. Testers are particularly important when drains are not present. Traditional testers funnel the water from the drench shower into a container to capture the water, allowing those providing maintenance to measure the delivery of the 20gpm minimum from the emergency showers.

Equipment Construction and Corrosive Materials

The ANSI/ISEA Z358.1-2014 standard states “emergency showers shall be constructed of materials that will not corrode in the presence of the flushing fluid.” The standard also states that valves must be corrosion resistant.

The equipment must withstand exposure to ambient airborne contaminants in the area of installation. This can be achieved by painting or coating the eyewash and/or shower systems or by using naturally corrosion resistant materials.

When selecting eyewash and shower equipment, including the supply system piping, make certain all parts and materials are compatible. For example, ensure materials that could adversely react with each other are not used together without adequate precautions taken to reduce or eliminate corrosion potential.

Flushing Fluid Attributes

It is generally agreed that immediately flushing the eyes or the skin with a suitable flushing fluid is the preferred first aid following a chemical eye splash.

It is critical that the flushing fluid maintain its pH balance and does not allow growth of bacterial colonies. In self-contained eyewash units, this is achieved by using a bacteriostatic additive. In personal wash units, this can be obtained by providing a sterile flushing fluid in a closed container which is only opened at the time of use.

Flushing Fluid Quality

For plumbed emergency eyewash stations and showers, the source of flushing fluid is typically potable tap water from a municipal or on-site water supply. Eyewash units should be constructed of noncorrosive materials. (The equipment owner must activate units weekly per the manufacturer’s maintenance instructions in order to inspect for any signs of contamination.)

Self-contained emergency eyewash units have a fixed reservoir of flushing fluid that is either prepared onsite by mixing potable water with preservatives to inhibit bacterial growth, or it may come pre-mixed in sealed containers. The flushing fluids may also contain buffered saline and additives to adjust pH levels. In most cases, the reservoir of flushing fluid has a limited life and will need to be changed by mixing fresh solution, or replacing the sealed containers as recommended by the manufacturer.

Self-contained eyewash units include sealed containers of sterile saline that is isotonic and pH controlled to mimic the eye’s natural chemistry. Such fluids may be supplied in personal wash units that may be bottles or other suitable containers. They offer bacteria-free flushing fluid, longer expiration periods and less frequent station maintenance.

Delivery Systems and Temperatures

To make certain an injured worker remains under the drench shower or washes his/her eyes for the full 15 minutes, as required in ANSI/ISEA Z358.1-2014, it is imperative that the flushing fluid be tepid (i.e. not be too hot, which could accelerate a chemical reaction, or too cold, which could be uncomfortable.) Based upon medical recommendations and various physiological studies, the ANSI/ISEA Z358.1-2014 standard requires that tepid flushing fluid be delivered. The acceptable flushing fluid temperature range is 60° – 100°F (16° – 38°C).

While there are many ways to deliver tepid water, users should first refer to the eyewash and shower manufacturers’ instructions and recommendations for delivering tepid water.

In many locations, the available supply of flushing fluid will be below 60° (16° C). When this is the case, the owner of the eyewash/shower unit must ensure that tepid flushing fluid is available. Whichever mechanism is used to temper flushing fluid, it must contain fail-safe features that allow delivery of the required amount of water for the fixture in the event of hot water supply failure. A variety of options exist:

Thermostatic Mixing Valves (TMV)

TMV’s blend hot and cold water to a specific tepid water temperature and maintain that temperature even when the incoming hot or cold water temperature changes. It is important to select a valve that is designed specifically for use with eyewash and drench shower equipment. These valves are designed to significantly reduce or shut off the flow of water when incoming cold water is interrupted so as not to allow scalding water to reach the safety fixtures. If the incoming hot water runs out or fails, cold water will continue to flow through the valves at all times. In an emergency, tepid water is best, but cold water is still better than no water at all. Check local plumbing codes to determine if the valve must meet American Society of Sanitary Engineering (ASSE) standard 1071.

Tankless Water Heaters

DTankless water heaters or on demand water heaters provide tepid water only as needed. Cold water is heated by gas or electricity as it flows through the heater. These products can support eyewash, drench showers, or combination units. They are equipped with safety shut offs to prevent scalding, but can still provide cold water if they lose power.

Heated Storage Tanks

A heated storage tank can be sized or designed to supply 15 minutes of tepid water by itself when used with other components to supply blended water at the recommended and desired temperature. An immersion heater is used to keep the water temperature tepid, or at the desired temperature, at all times. The tank can be self-contained or plumbed and should include safety measures to ensure scalding water is not delivered to eyewash, shower, drench hose or combination units. Note: a thermostatic mixing valve may be required by code in many jurisdictions because heated storage tanks cannot be relied on to maintain a safe temperature. Unheated storage tanks are not recommended for proving tepid water to emergency fixtures.

Testing and Maintenance

The presence of emergency equipment is not meaningful if the equipment is not maintained to be in working condition at all times.

To ensure that the eyewash or shower unit is in proper working order, the equipment owner should always follow the care instructions provided by the equipment manufacturer. This is especially true for self-contained units as the care criteria may vary given the number of flushing fluid options.

Equipment owners should be aware of the maintenance schedules found in the ANSI/ISEA Z358.1-2014 standard.

The standard calls for visual inspection of all self-contained devices to determine if the flushing fluid needs to be changed or supplemented. Visual inspections shall be conducted in accordance with the manufacturer’s instructions.

Self-contained equipment needs to be cleaned. Follow the manufacturer’s recommended cleaning schedule.

Weekly Testing

Plumbed devices must be tested weekly for a period long enough to verify operation and to ensure that flushing fluid is available. This is needed to flush out sediment and microbes, and to make certain flushing fluid is available at the shower head and the overall device is in working order.

The purpose of the weekly activation on plumbed emergency equipment is to ensure there is flushing fluid supply at the delivery head of the device and to clear the supply line of any sediment build-up that could prevent fluid delivery and to minimize microbial contamination due to standing water. While not intended the be a full 15-minute flow test, the duration of this test is dependent on the volume of water contained in the unit itself and all sections of pipe that do not form part of a constant circulation system. Water in these sections is static until a flow is activated by opening a valve. The goal is to flush out stagnant water in these “dead leg” portions completely. Consideration must also be given to systems that include mixing valves for hot and cold water supplies. Additionally, oxidizing media is available that can be placed in heated and storage tanks and in dead leg areas to eliminate microbial growth and limit contamination for extended periods.

Annual Inspections

All equipment must be inspected annually to ensure the device conforms to installation requirements. This applies to both plumbed and self-contained equipment. Annual testing is necessary to ensure the equipment functions properly and to ensure any changes in the area have not affected the safe use and operation of the equipment.

At a minimum, the equipment must perform according to the manufacturer’s instructions. This includes functional aspects such as placement of the spray heads, shower handle and the equipment itself in relation to the hazard. Site evaluation and testing results should be recorded and maintained to assure continued compliance to ANSI/ISEA Z358.1-2014.

The equipment owner should correct any and all situations that prevent a clear path to reach the equipment and ensure that the area remains well-lit and is easily identifiable.

ANSI/ISEA Z358.1-2014 Annual Inspection Checklist

Ensure Safety Compliance Today

Download the ANSI/ISEA Z358.1-2014 Inspection Checklist to keep your workplace up to standard.

Person Conducting Inspection:

Location of Equipment:

Date Inspected:

Emergency Equipment Type:

- ____

- ____

- ____

- ____

- Shower

- Eyewash

- Eye/Face Wash

- Combination Unit

For reference, the specific sections of ANSI/ISEA Z358.1-2014 should be consulted for additional information:

- Section 4. Emergency Showers

- Section 5. Eyewash Equipment

- Section 6. Eye/Face Wash Equipment

- Section 7. Combination Units

| ANSI/ISEA Z358.1-2014 Requirement | Inspection Evaluation | NOTES | |

|---|---|---|---|

| YES | NO | ||

| Is the equipment installed in accordance with manufacturer’s instructions? | |||

| Can the equipment be reached in 10 seconds when traveling from the location of the hazard? | |||

| Is the equipment on the same level as the hazard? | |||

| Is the path to the equipment free of obstructions? | |||

| Is there a highly visible sign indicating location of equipment? | |||

| Is the area around the equipment well-lit? | |||

| Does the delivered spray pattern meet the requirements of the equipment being inspected? | |||

| Is the delivered flushing fluid tepid? (60 – 100º F) | |||

| Does the flow rate meet the requirements of the equipment being inspected? | |||

| Does the valve remain open without the use of the operator’s hands? | |||

FREQUENTLY ASKED QUESTIONS ABOUT ANSI/ISEA Z358.12014

The following information answers commonly asked questions regarding the requirements set forth in the ANSI/ISEA Z358.1- 2014 standard.

Questions not covered in this section or questions requiring an interpretation of the standard’s criteria should be addressed to the International Safety Equipment Association (ISEA).

A: OSHA ‘s regulation 29 CFR part 1910.151(c) requires “Where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use.” While the regulation itself does not specify the ANSI/ISEA Z358.1-2014 standard, the agency’s letters of interpretation and inspection manuals make reference to the ANSI/ISEA Z358.1 standard as a means for employers to comply with health and safety requirements. In addition, various states specifically reference the ANSI/ISEA Z358.1 document in their respective regulations.

A: The standard does not provide application specific detail as to which types of equipment are required given the presence of a particular hazard in a work environment. Users should conduct a job hazard analysis and consult safety data sheets to assist with this decision. Another useful resource is the NIOSH Pocket Guide to Chemical Hazards. In addition, equipment manufacturers are a valuable resource to assist in evaluating the precise needs of the work area.

A: A faucet-mounted unit tested to and meeting the eyewash requirements may be considered to be compliant with the standard. It is critical to ensure these are properly installed to prevent hot water from being delivered to the eyes, which can create further damage to the eye tissue.

A: Eyewash and shower stations must be in accessible locations that require no more than 10 seconds to reach. The average distance travelled by most able-bodied persons in 10 seconds is approximately 55 feet. Special consideration should be given to employees with disabilities, and for work areas with highly injurious materials. The emergency shower shall be located on the same level as the hazard and the path of travel shall be free of obstructions that may inhibit its immediate use.

A: Some important dimensions for accessibility are: height of eyewash heads, eyewash knee clearance and height of shower valve handle. Consult with an ISEA member manufacturer for accessible equipment options.

A: Dust covers on eyewash heads are required to prevent build-up of particulates, which could enter the eye. Eyewash dust covers are designed to extricate themselves as soon as water flows from the outlet.

A: No. Third party certification is obtained by manufacturers of eyewash and shower equipment. ISEA members built this requirement into the standard to demonstrate their commitment to quality and end user safety.

A: Tepid water can come from different sources. Temperatures in excess of 38°C (100°F) have proven to be harmful to the eyes and can enhance certain chemical interaction with the skin and eye tissue. Recent information indicates that a temperature of 16°C (60°F) is suitable for the lower parameter for tepid flushing fluid without causing hypothermia to the equipment user.

A: The American Society of Sanitary Engineering (ASSE) standard 1071 sets performance requirements for temperature activated mixing valves used in conjunction with emergency equipment. Local plumbing codes may require mixing valves be compliant with ASSE 1071.

A: Consult your local authorities for assistance with applicable regulations. Consideration should be given to the proper disposal of waste flushing fluids from operating emergency eyewash and shower equipment. Freezing temperatures, drainage, elevated showers and pollutants are some, but not all, of the considerations.

ISEA Emergency Eye Wash and Shower Directory

- BRADLEY FIXTURES CORPORATION

- www.bradleycorp.com

- CINTAS

- www.cintas.com

- ENCON SAFETY PRODUCTS, INC.

- www.enconsafety.com

- BRADLEY FIXTURES CORPORATION

- www.gesafety.com

- HAWS

- www.hawsco.com

- HONEYWELL

- www.honeywellsafety.com

- HUGHES SAFETY

- www.hughes-safety.com

- PREVOR INC.

- www.prevor.com

- RADIANS

- www.radians.com

- SureWerx

- www.surewerx.com

Please consult with a safety and health professional or a representative from one of the manufacturers listed in this guide for a complete hazard assessment.

Aditional Information

Occupational Safety and Health Administration (OSHA)

200 Constitution Avenue, NW Washington, DC 20210

www.osha.gov

Information on voluntary standards can be obtained by contacting:

American National Standards Institute (ANSI)

25 West 43rd Street

New York, NY 10036

Phone: (212) 642-4900

www.ansi.org

For standard specific questions, please direct any requests for interpretation to the standards developing organization.

ISEA is the trade association for personal protective equipment and technologies:

International Safety Equipment Association (ISEA)

1101 Wilson Boulevard, Suite 1425

Arlington, VA 22209

Phone: (703) 525-1695

www.safetyequipment.org

NOTE: This guide is provided for informational purposes only and should not be used as a substitute for professional advice. The content is not guaranteed to be accurate, complete, reliable, current or error-free. By accessing this document, you accept and agree that following any information provided therein is at your own risk.